Stainless Steel Wire Rope Clips – Selection & Use Guide

1. What Are Stainless Steel Wire Rope Clips?

Stainless Steel Wire Rope Clips (also called wire rope clamps) are mechanical clamps used to secure the loose end of a wire rope to form eyes, loops, or temporary joints. They provide strong holding power and excellent corrosion resistance, especially when made of SS304 or SS316.

2. How to Select the Right Stainless Steel Wire Rope Clips

(1) Choose the Correct Material

-

SS304

-

General-purpose use

-

Indoor, light outdoor environments

-

-

SS316

-

Marine environments

-

High humidity, chemicals, salt spray

-

Best for long-term outdoor exposure

-

(2) Match the Clip Size to the Wire Rope Diameter

Always select a clip size equal to the rope diameter.

Common sizes: 3mm, 4mm, 6mm, 8mm, 10mm, 12mm, 16mm, 20mm.

Example:

-

6mm wire rope → use 6mm wire rope clips

-

10mm wire rope → use 10mm clips

Using the wrong size causes slippage or damage.

(3) Consider Clip Type

-

U-Bolt Wire Rope Clip (most common)

-

Wedge Socket Clip (for heavy loads & easy removal)

-

Double Saddle Clip (even rope compression; preferred for higher safety)

(4) Determine the Number of Clips Needed

Based on rope diameter and load requirement. Typical guideline:

| Rope Diameter | No. of Clips |

|---|---|

| 3–6 mm | 2 clips |

| 8–10 mm | 3 clips |

| 12–16 mm | 4 clips |

| 18–20 mm | 5 clips |

More clips = higher grip strength.

(5) Check Strength Requirements

Look for features such as:

-

Heavy-duty forged construction

-

Precision threads

-

Smooth saddle surface (prevents rope damage)

-

CE / EN standards if needed

3. How to Use Wire Rope Clips Correctly

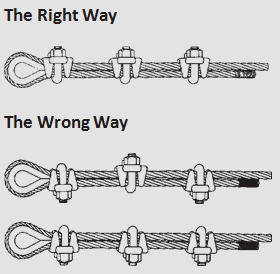

(1) Follow the “Never Saddle a Dead Horse” Rule

-

Saddle goes on the live (load-bearing) rope

-

U-bolt goes on the dead end

Incorrect installation significantly reduces holding strength.

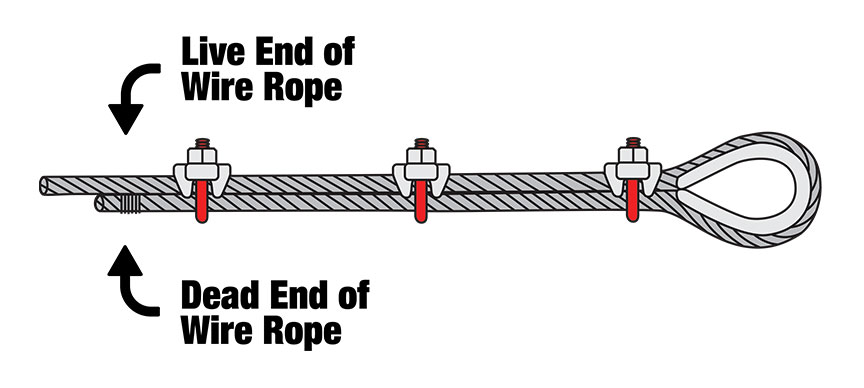

(2) Proper Installation Steps

-

Wrap wire rope to form a loop or eye.

-

Place the first clip at the end of the loop, saddle on the live line.

-

Tighten nuts evenly.

-

Install additional clips at correct spacing (≈ 6× rope diameter apart).

-

Tighten all nuts to recommended torque.

-

Load test, then re-tighten after rope settles.

(3) Torque Tightening

Each clip size has a recommended torque (Nm).

Under-tightening can cause slippage; over-tightening may crush the rope.

(4) Regular Inspection

Check periodically for:

-

Rope slippage

-

Bent U-bolts

-

Loose nuts

-

Corrosion or wear

Re-tighten nuts if necessary.

4. Common Applications

-

Marine & offshore rigging

-

Construction hoisting

-

Lifting and securing loads

-

Wire rope slings

-

Guard rails, fall protection

-

Shade sail & outdoor structures

-

Industrial machinery

-

Agriculture & fencing

-

DIY cable systems

They are essential hardware for any wire rope termination that needs strong and repeatable tightening.