Stainless Steel Chain – Selection & Use Guide

Stainless steel chain is widely used in marine, lifting, architectural, industrial, and outdoor environments.

Its corrosion resistance, high strength, and long service life make it ideal for demanding applications.

1. Types of Stainless Steel Chains

1.1 Short Link Chain

-

Compact links

-

Highest strength per meter

-

Best for lifting, hoisting, machinery, and marine use

1.2 Medium Link Chain

-

Versatile, general-purpose

-

Common for equipment, outdoor fixtures, and industrial applications

1.3 Long Link Chain

-

Lightweight and flexible

-

Suitable for decorative use, fencing, dog leashes, etc.

1.4 Calibrated Load Chain (for Hoists & Windlasses)

-

Precision link dimensions

-

Used in lifting devices and boat anchor windlasses

1.5 Welded Link vs. Unwelded Chain

-

Welded chain → strong, structural applications

-

Unwelded chain → lightweight, non-load-bearing decorative use

2. How to Select the Right Stainless Steel Chain

2.1 Choose the Material Grade

304 Stainless Steel

-

General purpose

-

Good corrosion resistance

-

For indoor, architecture, and light outdoor applications

316 Stainless Steel

-

Marine grade

-

Best resistance to saltwater, chemicals, and harsh weather

-

Ideal for boats, fishing, coastal construction, food processing

2.2 Determine Chain Size (Diameter)

Chain strength and working load depend on the wire diameter:

Typical examples:

-

3–4 mm: light-duty decorative or small equipment

-

5–6 mm: outdoor, fencing, small marine uses

-

8–10 mm: lifting, boat anchoring, industrial machinery

-

10–13 mm+: heavy-duty, hoisting, offshore use

2.3 Understand Working Load Limit (WLL)

When choosing a chain:

-

Check the WLL (provided by manufacturer)

-

Select a chain with 30–50% higher capacity than the expected load

-

For lifting → use certified lifting-grade chain only

2.4 Select Link Length According to Application

-

Short link: high strength, minimal stretching, lifting

-

Medium link: general-purpose rigging

-

Long link: flexible, fits larger hooks or shackles

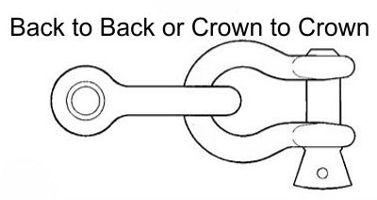

2.5 Compatibility with Other Hardware

Match the chain to:

-

Shackles

-

Turnbuckles

-

Hooks

-

Anchor swivels

-

Quick links

Pin and link size must fit correctly to avoid wear or slipping.

3. How to Use Stainless Steel Chains Safely

3.1 Proper Installation

-

Use compatible connectors (shackles, hooks, quick links)

-

Ensure all components have equal or higher WLL

-

Avoid improper connections such as bending or twisting links

3.2 Safe Operating Guidelines

-

Do not shock load stainless steel chain

-

Avoid side loading or knotting the chain

-

Never exceed the working load limit

-

Inspect regularly for wear or micro-cracks

3.3 Inspection & Maintenance

-

Check for link deformation, deep scratches, or elongation

-

Ensure welds are intact

-

Clean after saltwater exposure

-

Lubricate moving connections (shackles/hardware)

-

Store dry to prevent galvanic corrosion

4. Applications of Stainless Steel Chains

Marine & Offshore

-

Anchor chain

-

Mooring chain

-

Boat rigging

-

Fishing equipment

Industrial & Construction

-

Lifting and hoisting

-

Load securing

-

Machine pulling systems

Architecture & Outdoor

-

Shade sails

-

Suspension systems

-

Decorative hanging chains

-

Security chains

Food, Chemical & Clean Environments

-

Because stainless steel is hygienic and corrosion-resistant, it is ideal for:

-

Food processing equipment

-

Chemical plants

-

Pharmaceutical machinery

-

5. Stainless Steel Chain Specification Table

| Chain Size | Material | Link Type | Inside Length | Inside Width | WLL | Application |

|---|---|---|---|---|---|---|

| 4 mm | 304 SS | Short Link | 15 mm | 8 mm | 70 kg | General use |

| 6 mm | 316 SS | Medium Link | 18 mm | 10 mm | 250 kg | Marine / outdoor |

| 8 mm | 316 SS | Short Link | 24 mm | 12 mm | 450 kg | Anchor / lifting |

| 10 mm | 316 SS | Calibrated | 28 mm | 14 mm | 700 kg | Windlass / hoist |