Stainless Steel Turnbuckles – Selection & Use Guide

Stainless steel turnbuckles are precision tensioning devices used to adjust the length and tension of wire rope, chains, and cables. They are widely used in marine, due to

1. Turnbuckle Ty

1.1 Common End Fittings

Different end fittings are suitable for different connection methods:

-

Eye–Eye Turnbuckle

For permanent, secure connections with shackles, thimbles, wire rope, or bolts. -

Hook–Hook Turnbuckle

For quick connections where loads are lighter and non-critical. -

Jaw–Jaw Turnbuckle

Ideal for connecting to fixed points, eye bolts, wall plates, or wire rope thimbles. -

Eye–Jaw / Hook–Eye

Mixed combination for flexible installation.

1.2 Body Styles

-

Open Body Turnbuckle

Easy inspection of threads; widely used in rigging. -

Closed Body Turnbuckle (Architectural Turnbuckle)

Clean appearance, sleek design, ideal for architectural cables and stainless steel balustrades.

2. How to Select the Right Stainless Steel Turnbuckle

2.1 Choose Material Grade

-

304 Stainless Steel

Suitable for indoor, architecture, and light outdoor use. -

316 Stainless Steel

Best for marine environments, chemical plants, coastal regions, and harsh weather.

2.2 Determine Working Load Requirements

-

Each turnbuckle has a Working Load Limit (WLL).

-

Choose a turnbuckle with 20–30% higher load rating than your expected tension load.

-

For lifting applications, only use certified rigging hardware.

2.3 Match Turnbuckle Size to Rope or Cable

Turnbuckle size must match:

-

Wire rope diameter

-

Thread diameter

-

Pin size (for jaw type)

Example:

-

Wire rope 6 mm → Use M6–M8 turnbuckle

-

Wire rope 10 mm → Use M10–M12 turnbuckle

2.4 Choose the Proper End Fitting for Installation

-

Eye fittings: use with shackles, bolts, anchors

-

Hook fittings: for temporary tensioning

-

Jaw fittings: secure connection to fixed plates or thimbles

2.5 Check Thread Type

-

Right/Left threaded ends allow controlled tension adjustment

-

Ensure smooth threading before use

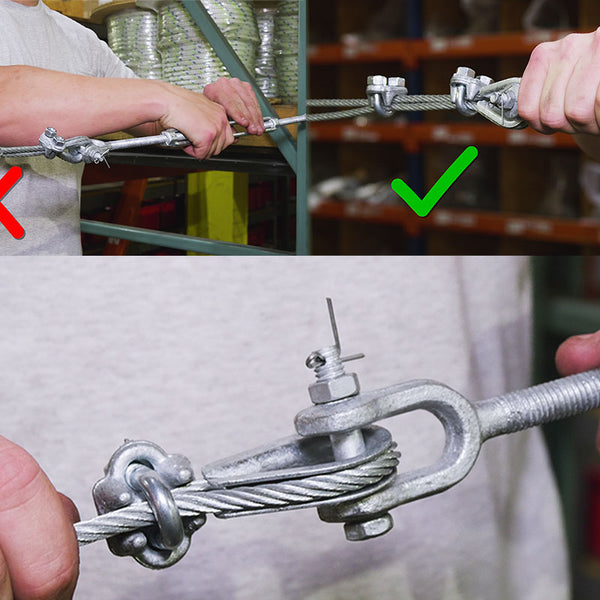

3. How to Use Stainless Steel Turnbuckles Safely

3.1 Installation Steps

-

Open the turnbuckle by rotating the body to extend both end fittings evenly.

-

Attach the two ends (jaw, eye, or hook) to the correct connection points.

-

Begin turning the body to tighten tension.

-

Keep both threaded ends inserted by at least 80% of their total length to avoid failure.

-

For critical installations, use locking pins or safety wires.

3.2 Avoid Common Mistakes

-

Do not use hook–hook types for heavy or critical loads.

-

Do not expose threads to cross-loading or bending forces.

-

Do not over-tighten — this may stretch or deform the fittings.

-

Do not use in lifting people or life-safety applications unless certified.

3.3 Maintenance

-

Rinse with freshwater after marine use.

-

Apply anti-seize lubricant to stainless steel threads to prevent galling.

-

Inspect regularly for wear, bending, or corrosion.

4. Applications of Stainless Steel Turnbuckles

Marine & Offshore

-

Sailboat rigging

-

Mooring & tension systems

-

Deck cable adjustments

Construction & Industrial

-

Load securing

-

Pipe supports

-

Machinery alignment

architecture & Decoration

-

Stainless cable railing / balustrade

-

Shade sails & outdoor tension structures

-

Wire rope suspension systems

Transport & Logistics

-

Cargo securing

-

Trailer tension systems

5. Technical Specification Template

| Model | Material | Type | Thread Size | End Fittings | WLL | Application |

|---|---|---|---|---|---|---|

| HT-01 | 304 SS | Open Body | M6 | Eye–Eye | 120 kg | Shade sail / railing |

| HT-02 | 316 SS | Open Body | M10 | Jaw–Jaw | 450 kg | Marine rigging |

| HT-03 | 316 SS | Closed Body | M12 | Eye–Jaw | 600 kg | Architectural cables |